Introduction

Wheel covers are more than just decorative pieces. They play a vital role in vehicle protection and efficiency. In today’s automotive industry, their durability is crucial for both aesthetics and functionality.

In this article, we will discuss the growing importance of durable wheel covers in the supply chain. You'll learn how they contribute to vehicle performance, safety, and operational efficiency.

The Role of Wheel Covers in Automotive Protection

Aesthetic vs. Practical Functions of Wheel Covers

Wheel covers serve both aesthetic and practical purposes. From a visual perspective, they can transform the look of a vehicle by covering the plain steel wheel with a more polished and uniform appearance. Whether you choose a sleek, glossy finish or a more classic design, wheel covers can elevate the vehicle's overall look, offering a more customized and appealing aesthetic.

On the practical side, wheel covers offer significant protection to the wheel. By acting as a barrier between the wheel and external elements, they shield the wheel from road debris, water, dirt, and corrosive chemicals. Without them, wheels are more susceptible to damage, which can lead to costly repairs or even replacements. This dual role of improving vehicle appearance while providing crucial protection makes wheel covers a key component in vehicle maintenance.

Protection from Environmental Factors

The wheel is constantly exposed to harsh environmental factors such as dirt, moisture, road salts, and chemicals. These elements can cause corrosion, rust, and deterioration over time, leading to expensive repairs. Wheel covers provide a protective layer, preventing these elements from coming into direct contact with the wheel. This protection is especially crucial in regions with harsh weather conditions, where road salt and moisture accelerate wear and tear.

By preventing rust and corrosion, wheel covers extend the life of the wheels, helping vehicle owners save money on repairs and replacements. This becomes particularly important in the context of the automotive supply chain, where the durability of components can directly impact the cost-effectiveness of the entire process.

Preventing Wear and Tear

In addition to protecting wheels from environmental factors, wheel covers help reduce wear and tear. Whether it's from rocks, potholes, or other road hazards, wheels are constantly at risk of being scratched, dented, or damaged. Wheel covers act as a shield, absorbing the impact from road debris and preventing direct contact with the wheel surface. This reduces the likelihood of wheel damage and keeps the vehicle in optimal condition for longer.

For companies involved in manufacturing or distributing automotive parts, wheel covers offer an easy and cost-effective solution to prevent damage during transportation and storage. This helps minimize the need for frequent repairs, ensuring smoother operations and cost savings throughout the supply chain.

Types of Wheel Covers and Their Durability

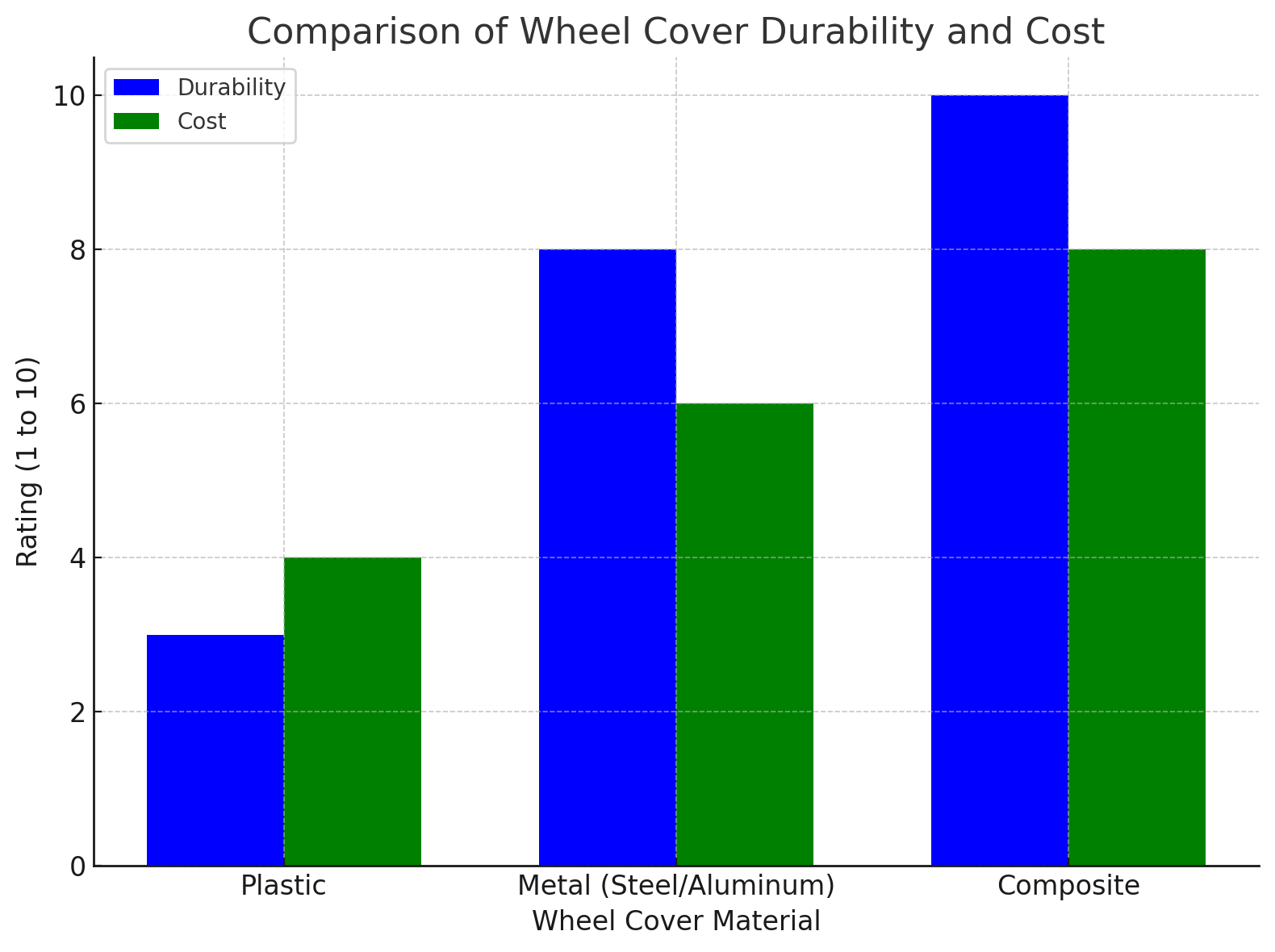

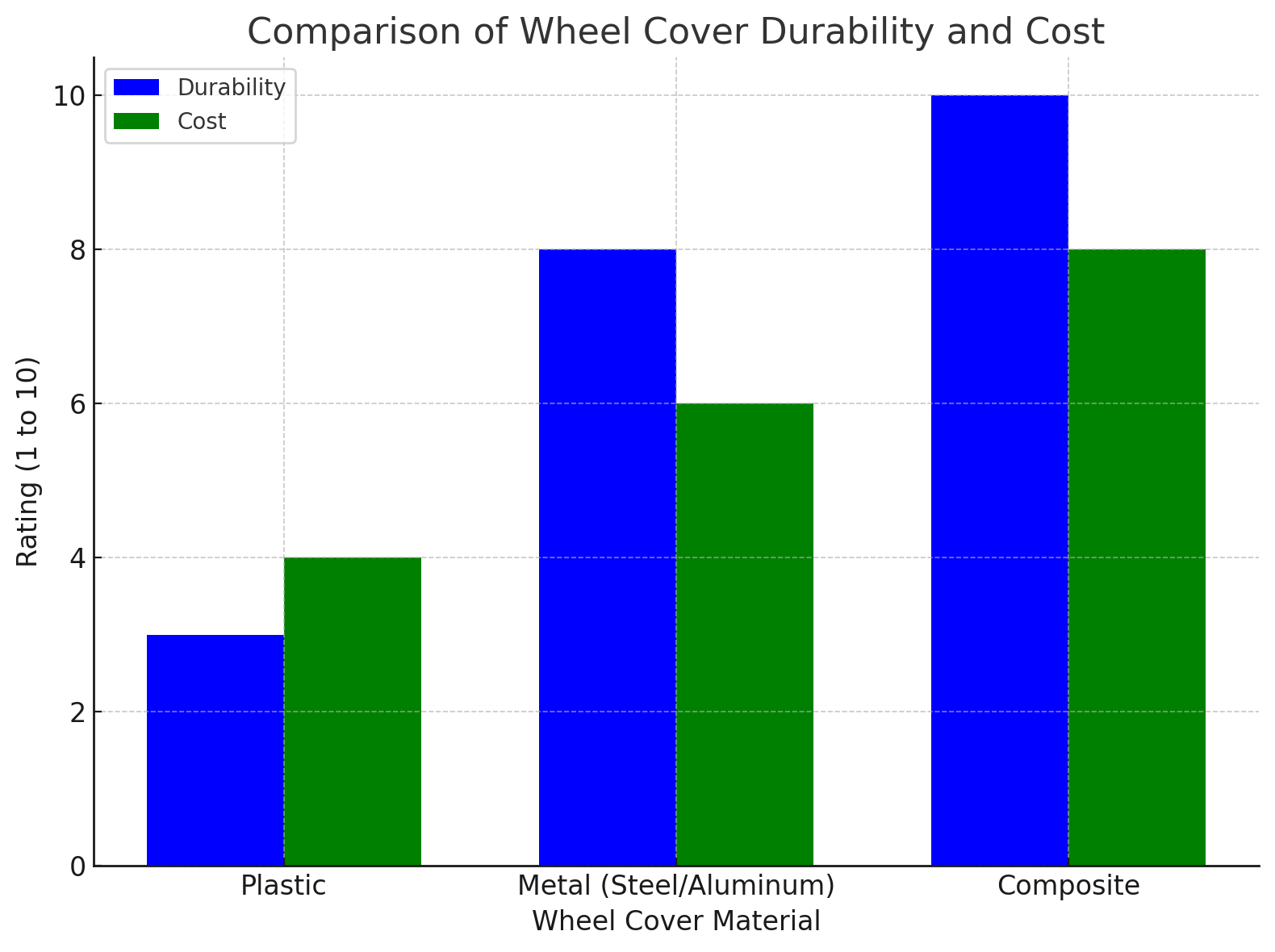

Material Variations: Plastic, Metal, and Composites

Wheel covers are made from a variety of materials, each offering different levels of durability, weight, and performance. The most common materials used for wheel covers include plastic, metal, and composites.

● Plastic Wheel Covers: These are lightweight and affordable but may not offer the same level of durability as metal or composite options. They are often used in budget vehicles or as temporary solutions but can still provide adequate protection from dirt and debris.

● Metal Wheel Covers: These offer superior strength and durability compared to plastic options. Made from stainless steel or aluminum, metal wheel covers provide long-lasting protection against road debris and environmental factors. However, they can be heavier, which may affect vehicle performance and fuel efficiency.

● Composite Wheel Covers: Composite materials, such as carbon fiber or advanced polymers, are becoming more popular in high-performance vehicles. These materials are lightweight, durable, and highly resistant to environmental damage. They offer enhanced protection without adding unnecessary weight, making them an ideal choice for vehicles where performance and efficiency are priorities.

Material | Durability | Weight | Protection Level | Cost |

Plastic | Medium | Light | Low | Low |

Metal (Steel/Aluminum) | High | Heavy | Medium | Medium |

Composite | Very High | Light | High | High |

Impact of Different Materials on Performance

The material used for wheel covers has a direct impact on both their durability and performance. For example, plastic covers, while cost-effective, may not withstand harsh impacts or environmental conditions as well as metal or composite options. Metal covers, while more durable, can add weight to the vehicle, which can affect fuel efficiency.

On the other hand, composite materials offer a perfect balance between durability and weight. These materials are designed to be strong enough to withstand harsh conditions while being light enough to avoid negatively impacting the vehicle's performance. This makes composite wheel covers a popular choice for high-end vehicles, especially those designed for performance or fuel efficiency.

Longevity: How to Choose the Most Durable Wheel Cover

When selecting a wheel cover, it's essential to consider its longevity, especially in the context of the supply chain. Companies looking to invest in wheel covers should prioritize materials known for their durability and resistance to environmental wear. Composite materials, for example, offer a longer lifespan than plastic, and they are less likely to crack or degrade over time.

Factors such as the vehicle's intended use, climate conditions, and transportation methods should also be taken into account when choosing the right wheel cover. In the automotive supply chain, selecting durable wheel covers can minimize the need for replacements and reduce overall maintenance costs.

Wheel Cover Type | Durability | Cost Over Time | Performance Impact |

Low-Quality | Low | High | Poor |

Medium-Quality | Medium | Medium | Good |

High-Quality | High | Low | Excellent |

Durability of Wheel Covers in the Supply Chain Context

Wheel Covers in Transportation and Logistics

The transportation and logistics sectors face a variety of challenges when moving automotive parts, including the risk of damage to sensitive components like wheels. Wheel covers help mitigate these risks by providing a protective shield for the wheels during shipping and handling. This is particularly important for businesses involved in global trade, where components may be exposed to rough handling, extreme temperatures, or other hazards.

By investing in durable wheel covers, companies can protect their products and reduce the likelihood of damage during transport. This ensures that wheel covers and other automotive parts arrive in optimal condition, ready for installation or distribution.

Durability in Harsh Conditions

During transportation, wheel covers are often subjected to extreme environmental conditions, such as high humidity, saltwater exposure, and temperature fluctuations. Wheel covers made from high-quality materials like composites or metals are better equipped to withstand these harsh conditions, ensuring that the wheels remain protected throughout the shipping process.

For example, composite wheel covers offer excellent resistance to corrosion and are lightweight, making them ideal for vehicles that will be shipped across different climates. This durability in the face of challenging conditions makes durable wheel covers a wise investment for any company operating in the automotive supply chain.

The Role of High-Quality Wheel Covers in Reducing Costs

Investing in durable wheel covers can result in significant cost savings for companies. High-quality wheel covers help prevent damage to wheels during shipping, reducing the need for repairs and replacements. By protecting the wheels from the elements, companies can also reduce the frequency of maintenance, which can be costly and time-consuming.

In the automotive supply chain, reducing the risk of damage and extending the lifespan of wheel covers can help companies achieve greater operational efficiency and lower overall costs. This makes the selection of durable, high-quality wheel covers an essential consideration for any business involved in manufacturing, distribution, or retail.

The Impact of Wheel Covers on the Supply Chain Efficiency

Reducing Downtime in Manufacturing and Distribution

Durable wheel covers play a vital role in reducing downtime in both manufacturing and distribution. By preventing damage during production and shipment, wheel covers ensure that products remain in optimal condition. This reduces delays caused by repairs or replacements, helping to keep production and distribution processes on track.

Furthermore, when wheel covers protect the wheels from damage, they also contribute to the efficiency of the supply chain by minimizing the need for additional resources to fix or replace damaged components. This improves overall productivity and ensures that businesses can meet their deadlines and customer demands.

Streamlining Maintenance with Durable Wheel Covers

Maintenance is a significant factor in the automotive industry, both in terms of vehicle upkeep and the management of parts within the supply chain. Durable wheel covers help streamline maintenance by reducing the frequency of repairs needed for wheels. This lowers the overall maintenance cost, allowing businesses to allocate resources to other areas of their operations.

For example, by using durable wheel covers, companies can avoid costly wheel replacements and repairs that would otherwise be required due to environmental damage or wear and tear. This leads to more efficient operations and better cost management throughout the supply chain.

The Importance of Wheel Covers for Global Logistics

As global trade continues to expand, the need for durable wheel covers in logistics becomes increasingly important. Whether transporting vehicles or individual components, wheel covers help ensure that wheels remain intact and functional, even after long journeys across various climates and environments. By using durable materials that can withstand the rigors of international shipping, businesses can maintain product quality and meet customer expectations.

Technological Innovations in Wheel Covers

Advanced Materials and Manufacturing Techniques

In recent years, there have been significant innovations in the materials and manufacturing techniques used for wheel covers. Advanced materials such as carbon fiber, composites, and lightweight polymers are now being used to create stronger, more durable wheel covers that offer superior protection and performance.

Manufacturing techniques like injection molding and compression molding also allow for greater precision and consistency in the production of wheel covers. These advancements in technology are helping to improve the quality and durability of wheel covers, ensuring that they meet the evolving demands of the automotive industry.

Aerodynamics and Performance Enhancements

One of the most significant trends in wheel cover design is the integration of aerodynamics to enhance vehicle performance. By reducing drag and improving fuel efficiency, aerodynamic wheel covers contribute to better overall vehicle performance. This is particularly relevant for electric vehicles and high-performance cars, where every component is designed to optimize efficiency.

Aerodynamic wheel covers can help reduce fuel consumption and increase the vehicle's range, making them an attractive option for car manufacturers and consumers alike. This growing focus on aerodynamics is driving innovation in wheel cover design and material selection.

Sustainable Manufacturing Practices

Sustainability is an increasingly important consideration in the automotive industry. Many manufacturers are now turning to eco-friendly materials and sustainable manufacturing practices to reduce their environmental impact. This includes using recycled materials in the production of wheel covers, which not only helps reduce waste but also lowers the carbon footprint of the manufacturing process.

By adopting sustainable practices, companies can meet the growing consumer demand for environmentally responsible products while also improving their bottom line. Sustainable wheel covers contribute to a greener, more sustainable automotive industry.

Challenges in Manufacturing and Exporting Durable Wheel Covers

Navigating Trade Regulations and Standards

Manufacturers of wheel covers must navigate a complex landscape of international trade regulations and standards. These regulations vary by region and can affect everything from material selection to manufacturing processes. Compliance with these standards is crucial to ensure that products can be legally exported and sold in different markets.

For companies in the automotive supply chain, understanding and adhering to these regulations is essential for ensuring smooth operations and avoiding potential delays or penalties.

Managing Supply Chain Disruptions

Supply chain disruptions, such as natural disasters, political instability, and global pandemics, can have a significant impact on the manufacturing and distribution of wheel covers. These disruptions can lead to delays in production, shipping, and delivery, which can affect the overall efficiency of the supply chain.

To mitigate the effects of these disruptions, companies must develop strategies to manage risks and ensure the continued availability of high-quality wheel covers. This may involve diversifying suppliers, building more resilient supply chains, or investing in digital logistics solutions.

Counterfeit Products and Quality Control

Counterfeit wheel covers pose a significant threat to product integrity and brand reputation. In the global market, counterfeit products are often difficult to detect and can undermine consumer confidence in legitimate manufacturers. Companies must take steps to protect their intellectual property and ensure that their products meet the highest quality standards.

By implementing robust quality control processes and utilizing technology to track and authenticate products, companies can reduce the risk of counterfeit products entering the market.

Conclusion

Durable wheel covers are essential for protecting wheels, boosting vehicle performance, and enhancing supply chain efficiency. High-quality covers help reduce maintenance costs, prevent damage, and improve operations, offering significant savings. As the automotive industry evolves, durability and innovation in wheel covers will become even more critical. SEIKOSHOWA provides cutting-edge products designed for long-lasting performance, offering unmatched value to businesses in a competitive global market.

FAQ

Q: What is the role of a durable wheel cover in the automotive supply chain?

A: A durable wheel cover protects wheels from damage during transportation and handling. It also helps reduce maintenance costs and improve overall supply chain efficiency by preventing corrosion and wear.

Q: How do wheel covers contribute to vehicle performance?

A: Wheel covers help enhance vehicle performance by reducing road debris and moisture exposure. They protect wheels from damage, improving the vehicle's longevity and efficiency.

Q: Why should businesses invest in high-quality wheel covers?

A: Investing in high-quality wheel covers ensures better protection, reduces long-term repair costs, and streamlines operations, ultimately leading to cost savings in the supply chain.

Q: What materials are typically used in durable wheel covers?

A: Durable wheel covers are made from materials like plastic, metal, and composites. These materials offer varying degrees of protection, durability, and weight, tailored to different vehicle needs.

Q: How can wheel covers reduce supply chain disruptions?

A: Wheel covers protect wheels from damage during storage and transportation, ensuring that products arrive intact and reducing delays due to wheel repairs or replacements.