Introduction

In the automotive industry, vehicle performance and stability depend heavily on high-quality shock absorbers. These components are critical for maintaining ride comfort, safety, and overall handling. However, managing a reliable supply chain for car shock absorbers presents unique challenges, such as balancing cost with quality, addressing disruptions, and meeting customer expectations.

In this article, we’ll explore how optimizing the shock absorber supply chain can significantly improve product stability and enhance customer satisfaction. You will learn strategies for streamlining operations, improving logistics, and leveraging advanced technologies to achieve superior results.

The Importance of Shock Absorbers in Automotive Supply Chains

Defining Shock Absorbers and Their Role in Vehicle Performance

Car shock absorbers are integral components of a vehicle’s suspension system. They help to stabilize the vehicle by controlling the oscillation of the springs and ensuring that the tires remain in constant contact with the road. By damping the movement caused by bumps or rough terrain, shock absorbers significantly enhance ride comfort and handling. Without proper shock absorbers, vehicles would experience excessive bouncing, reduced control, and increased wear on other suspension components. This would compromise both safety and vehicle longevity, making shock absorbers essential for maintaining optimal vehicle performance.

How Supply Chain Optimization Affects Shock Absorber Quality

The quality of shock absorbers directly impacts the overall performance of a vehicle. Optimizing the supply chain for shock absorbers involves streamlining the procurement of raw materials, manufacturing processes, and distribution methods to ensure consistency and reliability. An efficient supply chain ensures that manufacturers receive high-quality parts on time, which directly influences product performance. Furthermore, a well-optimized supply chain helps reduce defects, maintain standards, and eliminate delays that could otherwise lead to compromised product quality or performance issues. When shock absorbers are sourced and produced efficiently, they can better meet the stringent safety and performance standards expected in the automotive industry.

Key Challenges in Shock Absorber Supply Chain Management

Supply Chain Disruptions and Their Impact on Product Stability

Supply chain disruptions can arise from various factors, such as material shortages, transportation delays, geopolitical tensions, or unforeseen global events. These disruptions can severely affect the production and distribution of shock absorbers, leading to production delays, stockouts, and increased operational costs. For instance, if a supplier experiences delays in delivering raw materials like steel or rubber, it can cause a bottleneck in the shock absorber manufacturing process. Such disruptions may ultimately compromise product stability, delaying vehicle production and leaving customers unsatisfied due to missed delivery deadlines.

Balancing Cost and Quality in Supply Chain Management

One of the most significant challenges in optimizing a shock absorber supply chain is finding the right balance between cost efficiency and maintaining high-quality standards. While reducing costs is important for maintaining competitive pricing, cutting corners on the quality of materials or manufacturing processes can negatively impact product performance. Ensuring that shock absorbers meet safety standards and deliver the expected durability requires manufacturers to carefully manage their supply chain costs without sacrificing quality. Companies must invest in reliable suppliers and efficient production processes while keeping operational costs under control to ensure the final product meets both cost and quality expectations.

Factor | Impact on Supply Chain | Strategies to Optimize |

Supplier Relationships | Reliability and transparency in product delivery | Strengthen communication, diversify suppliers |

Material Shortages | Delays in production and delivery | Maintain buffer stocks, forecast demand |

Cost vs. Quality Balance | Risk of compromising product quality for cost | Invest in quality, use JIT systems to reduce waste |

Logistics and Delivery | Impact on timely delivery and customer satisfaction | Optimize transportation and warehousing systems |

Technology Integration | Real-time tracking and predictive analytics | Implement IoT, AI, blockchain for monitoring |

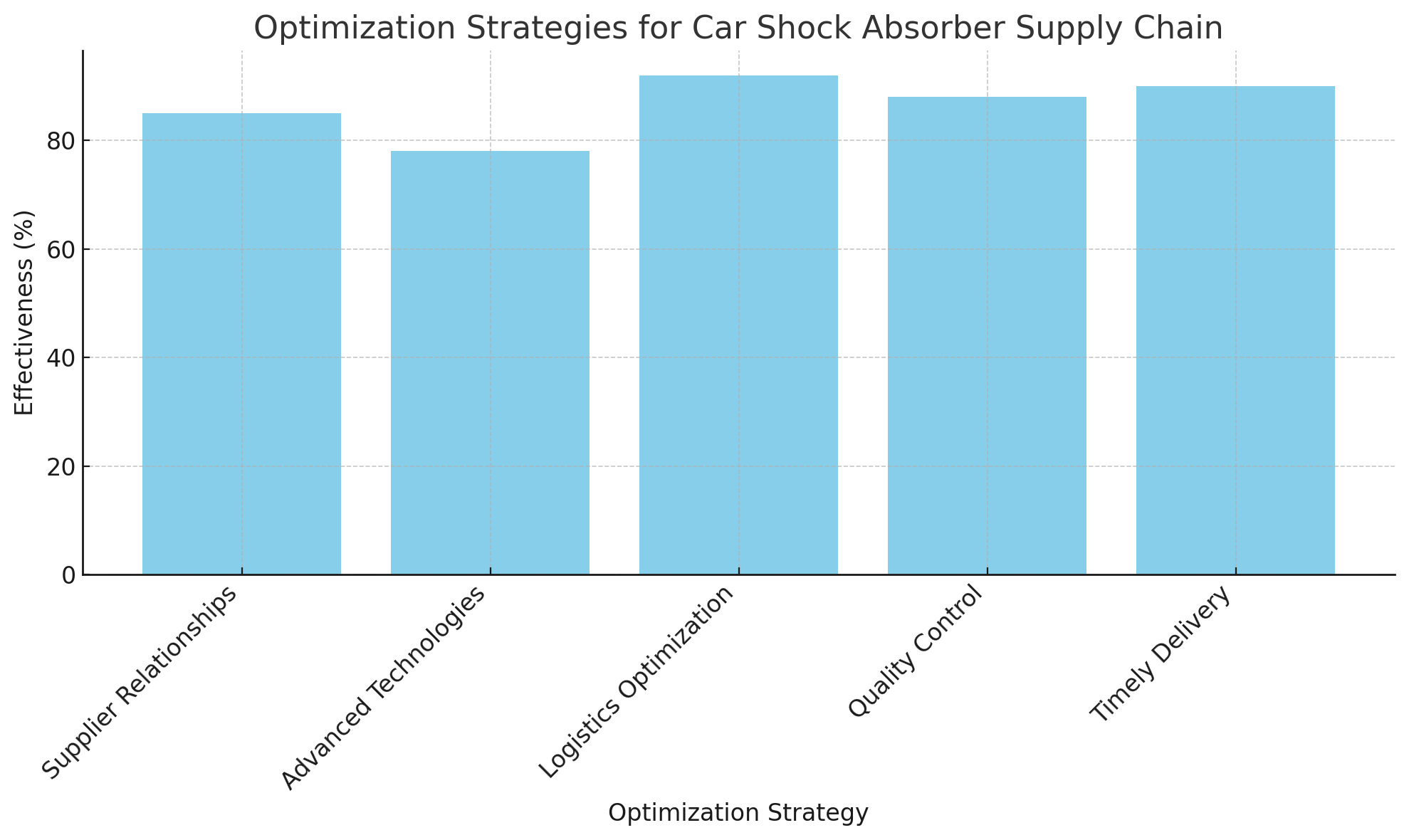

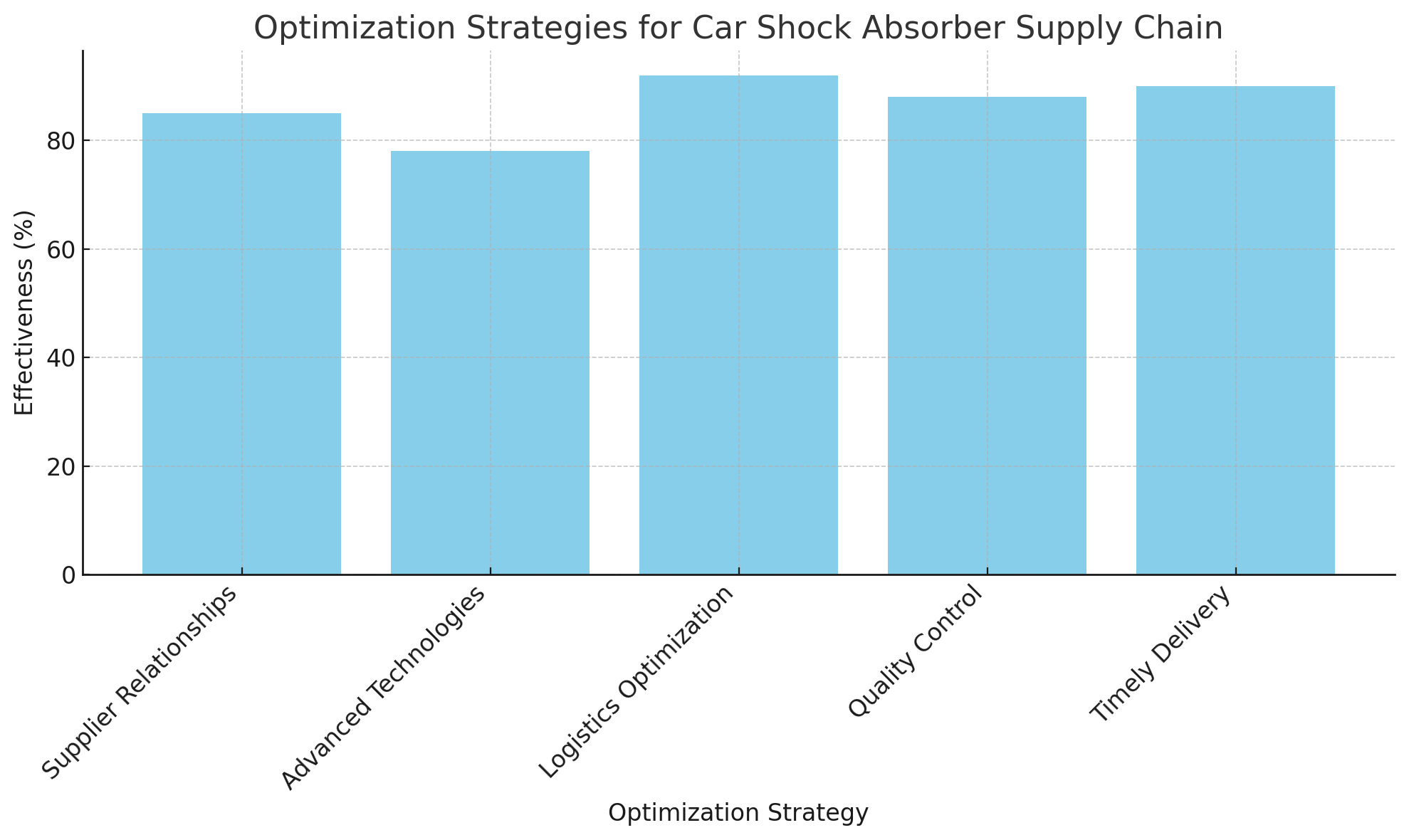

Strategies for Optimizing the Shock Absorber Supply Chain

Enhancing Supplier Relationships and Communication

Strong relationships with suppliers are crucial for ensuring timely deliveries and maintaining high product standards. Clear communication between manufacturers and suppliers helps to prevent misunderstandings, reduce lead times, and ensure that materials and components are delivered when needed. By building a network of trusted suppliers, manufacturers can reduce the risk of disruptions and improve the overall reliability of their supply chain. Furthermore, collaborating with suppliers can lead to innovative solutions, such as better materials or more efficient manufacturing methods, which can ultimately improve the performance of the shock absorbers produced.

Implementing Advanced Technologies for Real-Time Monitoring

The adoption of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and blockchain is revolutionizing supply chain management. These technologies enable real-time tracking of inventory, production progress, and shipping schedules, providing manufacturers with valuable data to optimize their supply chain. With IoT sensors, manufacturers can monitor the condition of raw materials and components, while AI can predict potential disruptions or supply chain bottlenecks. Blockchain ensures transparent and secure transactions, enhancing trust and reducing fraud in the supply chain. By leveraging these technologies, manufacturers can anticipate issues before they arise and take proactive measures to keep the shock absorber supply chain running smoothly.

Leveraging Just-In-Time (JIT) and Lean Inventory Systems

Just-In-Time (JIT) and lean inventory systems have been widely adopted in various industries to minimize waste and improve production efficiency. These systems are particularly effective in managing the flow of shock absorbers and other components, ensuring that only the necessary quantity of parts is produced and stored at any given time. This reduces holding costs and allows manufacturers to quickly respond to fluctuations in demand. By maintaining flexible inventory levels, manufacturers can ensure they always have the right parts available without overstocking or causing unnecessary delays in production.

Benefit | Description | Impact on Customer Satisfaction |

Reduced Lead Times | Faster production and delivery | Timely product delivery enhances customer loyalty |

Improved Product Quality | Consistent quality control and testing | Higher reliability and trust in products |

Cost Efficiency | Streamlined operations reduce overhead costs | Competitive pricing with maintained quality |

Better Supplier Reliability | Stronger supplier partnerships | Fewer disruptions, leading to on-time deliveries |

Enhanced Inventory Management | Real-time tracking and optimized stock levels | Improved availability of products for customers |

Improving Product Stability Through Efficient Logistics

Streamlining Logistics and Delivery Processes

Logistics play a vital role in the efficiency of the shock absorber supply chain. Optimizing the transportation and warehousing processes ensures that shock absorbers are delivered on time and in good condition. Effective logistics management reduces delays, lowers shipping costs, and enhances the overall customer experience. For manufacturers, this means establishing efficient routes, using the right packaging, and partnering with reliable logistics providers to ensure timely deliveries. Streamlining logistics also helps to prevent inventory congestion and minimize stockouts, ensuring a steady flow of shock absorbers to meet customer demand.

Reducing Lead Times and Enhancing Customer Satisfaction

Reducing lead times is essential for maintaining customer satisfaction. Longer wait times for shock absorber deliveries can delay vehicle production, leading to frustrated customers and potential loss of sales. By optimizing the supply chain, manufacturers can reduce lead times and ensure that shock absorbers are available when needed. This helps meet customer expectations for timely product availability and strengthens relationships between manufacturers and their customers. The ability to deliver products quickly and consistently is a key factor in building trust and enhancing customer loyalty.

The Role of Quality Control in the Supply Chain

Implementing Rigorous Quality Standards for Shock Absorbers

Quality control is paramount in shock absorber manufacturing. Shock absorbers must meet strict safety and durability standards to ensure the vehicle's performance and the safety of its passengers. Manufacturers must implement rigorous testing procedures to assess the shock absorbers' ability to withstand various driving conditions, including rough roads, extreme temperatures, and heavy loads. By enforcing high-quality standards at every stage of the production process—from material selection to final assembly—manufacturers can guarantee that their shock absorbers meet the necessary performance criteria and are free of defects.

Testing and Validation Processes to Ensure Product Reliability

To ensure that shock absorbers perform consistently over time, manufacturers must subject them to a range of tests. These tests include endurance testing, where shock absorbers are subjected to extreme conditions to verify their longevity, as well as dynamic testing to ensure they function as intended during vehicle operation. A well-designed validation process also includes testing for factors such as corrosion resistance and vibration damping performance. By incorporating these tests into the supply chain, manufacturers can improve product reliability and reduce the risk of defects that could lead to recalls or customer complaints.

Quality Control Process | Description | Impact on Supply Chain |

Raw Material Inspection | Checking the quality of materials before production | Ensures high-quality components for manufacturing |

In-Process Testing | Ongoing checks during assembly | Detects issues early to prevent production delays |

End-Product Validation | Testing final shock absorbers for durability and performance | Guarantees that the product meets customer expectations |

Compliance with Standards | Adhering to regulatory and industry standards | Ensures product reliability and safety for end users |

The Impact of Optimizing Shock Absorber Supply Chains on Customer Satisfaction

Meeting Customer Expectations for Reliable and Durable Products

Customer satisfaction is closely tied to the reliability and durability of the products they receive. In the automotive industry, customers expect that their vehicles will perform consistently and remain safe for years. By optimizing the shock absorber supply chain, manufacturers can ensure that their products meet these expectations. Reliable shock absorbers that perform well over time not only improve the driving experience but also enhance customer trust and brand loyalty.

How Timely Delivery Enhances Customer Loyalty

Timely delivery is a critical factor in customer satisfaction. For automotive manufacturers, ensuring that shock absorbers arrive on time is essential to avoid production delays and meet delivery deadlines. When shock absorbers are delivered on schedule, it allows vehicle production to proceed smoothly, helping manufacturers meet customer demands. On-time delivery also enhances customer loyalty by demonstrating reliability and a commitment to customer needs.

Conclusion

Optimizing shock absorber supply chains is essential for enhancing product stability and vehicle performance. By strengthening supplier relationships, using advanced technologies, and improving logistics, manufacturers can ensure better quality and timely delivery. High-quality standards and thorough testing help meet customer expectations, leading to improved reliability and satisfaction. Partnering with trusted companies like SEIKOSHOWA offers innovative solutions and high-quality shock absorbers, supporting manufacturers in staying competitive in a dynamic market.

FAQ

Q: What is a Car Shock Absorber and why is it important in supply chains?

A: A Car Shock Absorber is a key component in a vehicle’s suspension system. It helps maintain stability, improves ride comfort, and ensures vehicle safety. Optimizing its supply chain is crucial for ensuring timely delivery, high product quality, and customer satisfaction.

Q: How does optimizing the Car Shock Absorber supply chain improve product stability?

A: By streamlining processes, enhancing supplier relationships, and using real-time technologies, manufacturers can reduce disruptions, maintain consistent product quality, and improve shock absorber performance, leading to better vehicle stability.

Q: What challenges do manufacturers face in managing Car Shock Absorber supply chains?

A: Common challenges include supply chain disruptions, material shortages, and balancing cost with quality. These issues can impact product quality, delay deliveries, and affect customer satisfaction, making optimization critical for stable production.

Q: How can advanced technologies improve the Car Shock Absorber supply chain?

A: Advanced technologies like IoT and AI allow real-time monitoring, predictive analytics, and automated decision-making. This helps prevent disruptions, optimize inventory management, and ensure consistent product quality for shock absorbers.

Q: How does efficient logistics impact Car Shock Absorber supply chains?

A: Optimizing logistics ensures timely delivery, reduces lead times, and helps meet customer expectations. Efficient transportation and warehousing systems improve the overall performance and reliability of Car Shock Absorbers, boosting customer satisfaction.