Introduction

The automotive industry is evolving rapidly, and wheel covers are at the forefront of this change. Once just a visual upgrade, high-quality wheel covers now enhance vehicle performance, aesthetics, and sustainability. With rising demand for eco-friendly and customizable solutions, wheel covers are becoming essential in both manufacturing and the aftermarket.

In this article, we will explore how quality wheel covers are shaping the future of automotive design. You will learn how innovations in materials and manufacturing processes are driving sustainable growth in the industry.

The Role of Quality Wheel Covers in Automotive Manufacturing

Enhancing Vehicle Performance through Durable Wheel Covers

Quality wheel covers are pivotal in improving vehicle performance. Modern covers made from lightweight materials such as carbon fiber and aluminum alloys contribute to better aerodynamics, reducing drag and improving fuel efficiency. These materials also help reduce the overall weight of vehicles, which enhances acceleration and handling. Durable wheel covers offer superior protection, shielding wheels from dirt, debris, and harsh environmental factors, ensuring longevity and reliability.

Impact on Vehicle Aesthetics and Customization

Wheel covers provide an opportunity for vehicle owners and manufacturers to customize vehicles with unique styles. Whether it's a bold, metallic finish or a sleek, matte design, wheel covers allow car owners to express their individuality. As consumers increasingly demand personalized cars, wheel covers have become a crucial aftermarket accessory. Manufacturers are also taking note, offering customized wheel cover designs that cater to specific market niches.

Cost-Effectiveness in Vehicle Production

Using high-quality wheel covers in vehicle manufacturing can also be cost-effective. Instead of opting for expensive alloy wheels, manufacturers can provide affordable yet visually appealing alternatives through well-designed wheel covers. This allows manufacturers to meet consumer demand for aesthetically pleasing vehicles while keeping production costs manageable. Additionally, durable wheel covers extend the lifespan of wheels, reducing the need for costly repairs or replacements.

Aftermarket Demand for High-Quality Wheel Covers

Rising Consumer Demand for Customization and Personalization

As the automotive aftermarket industry grows, the demand for customizable products like wheel covers has surged. Consumers today are keen on personalizing their vehicles to reflect their unique style. Wheel covers allow for quick, affordable customization compared to other vehicle modifications, making them a popular choice in the aftermarket space. Custom designs, colors, and materials offer car enthusiasts the freedom to modify their vehicles without significant financial investment.

Increased Adoption of Sustainable Materials

Sustainability is an important factor driving demand in the aftermarket sector. As eco-consciousness grows, consumers are opting for products made from sustainable materials. The wheel cover industry has responded by incorporating recycled plastics, biodegradable composites, and other environmentally friendly materials into production. This shift not only meets consumer expectations but also aligns with the broader automotive industry's move towards greener alternatives.

Performance Benefits in the Aftermarket Sector

High-performance wheel covers are increasingly popular in the aftermarket industry due to their ability to improve fuel efficiency, handling, and safety. For example, lightweight wheel covers reduce vehicle weight, improving fuel economy and reducing carbon emissions. They also help in managing the vehicle’s performance during demanding driving conditions, such as off-road adventures. These performance enhancements make quality wheel covers a valuable addition for both vehicle owners and manufacturers.

Advantage | Impact on Consumer |

Customization Options | Ability to personalize vehicle aesthetics |

Cost-Effective Replacement | Cheaper than purchasing new wheels |

Improved Vehicle Performance | Better fuel efficiency and wheel protection |

Eco-friendly Materials | Meets sustainability demands |

Technological Advancements in Wheel Cover Manufacturing

Innovation in Materials: Lightweight Alloys and Carbon Fiber

The wheel cover industry has witnessed major advancements in materials. Lightweight alloys such as aluminum and magnesium, alongside carbon fiber, are now common in wheel cover production. These materials not only offer a high strength-to-weight ratio but also provide better durability and impact resistance. As vehicle manufacturers seek more efficient and durable components, these materials have become integral to the production of modern wheel covers.

3D Printing and Customization for Better Fit and Design

3D printing technology is revolutionizing wheel cover production. It allows for the creation of highly customized designs with improved fit and precision. Consumers can now choose wheel covers that perfectly match the contours and specifications of their vehicles, making it a game-changer for the aftermarket industry. 3D printing also enables the rapid prototyping of new designs, reducing production time and costs for manufacturers.

Integration of Smart Technology in Wheel Covers

The integration of smart technology into wheel covers is another exciting development. Manufacturers are now incorporating sensors that monitor tire pressure, temperature, and even road conditions. Additionally, some wheel covers feature LED lighting, improving visibility and safety. As vehicles become more connected, wheel covers are evolving into high-tech components that provide additional functionality while enhancing vehicle aesthetics.

Material | Advantages | Disadvantages |

Aluminum | Lightweight, durable, corrosion-resistant | Can be more expensive than plastic options |

Carbon Fiber | High strength-to-weight ratio, sleek appearance | Expensive, not as widely available |

Recycled Plastics | Eco-friendly, cost-effective | Less durable compared to metals |

Stainless Steel | Very durable, corrosion-resistant | Heavier, more costly |

The Role of Wheel Covers in Promoting Sustainability

Eco-Friendly Materials and Recycling in Wheel Cover Production

Sustainability is a key trend in the automotive industry, and wheel covers are no exception. Many manufacturers are turning to eco-friendly materials like recycled plastics and biodegradable composites. By using these materials, manufacturers not only reduce waste but also appeal to environmentally conscious consumers. The focus on recycling is critical as the automotive sector aims to reduce its carbon footprint and move toward more sustainable production methods.

Reducing Environmental Impact with Lightweight Materials

Lightweight wheel covers help reduce a vehicle's overall weight, which in turn lowers fuel consumption and emissions. The adoption of lightweight materials like carbon fiber and aluminum alloys is driving this shift, as these materials provide the necessary strength without adding unnecessary weight. As a result, vehicles equipped with these advanced wheel covers contribute to better fuel efficiency and a smaller environmental footprint.

Regulatory Pressures and the Shift Towards Green Manufacturing

Increasingly strict environmental regulations are pushing automotive manufacturers to adopt greener manufacturing practices. This includes using more sustainable materials, reducing energy consumption in the production process, and ensuring that wheel covers meet environmental standards. As regulatory pressures intensify, manufacturers that invest in green manufacturing technologies will be better positioned to comply and thrive in the evolving automotive landscape.

Regional Insights and Growth Opportunities

Growth in Emerging Markets: Asia-Pacific and Latin America

The demand for wheel covers is growing rapidly in emerging markets such as Asia-Pacific and Latin America. These regions are seeing a rise in vehicle ownership, and consumers are increasingly interested in customizing their cars. As disposable incomes rise and more people purchase vehicles, the market for wheel covers will continue to expand. Manufacturers that target these regions with cost-effective, durable, and customizable wheel covers will stand to gain a competitive edge.

Region | Growth Driver | Projected Growth Rate (CAGR) |

North America | Focus on luxury and tech-integrated covers | 5.4% |

Europe | Customization and sustainability focus | 5.6% |

Asia-Pacific | Cost-effective manufacturing, rising vehicle ownership | 5.9% |

Latin America | Growing middle class and vehicle demand | 6.0% |

Key Trends in North America and Europe

North America and Europe remain key markets for high-quality wheel covers, driven by consumer demand for premium products and vehicle customization. In these regions, the preference for high-performance and aesthetic appeal is driving innovation in wheel cover designs. Manufacturers are focusing on offering more sustainable and customizable options to meet the needs of discerning consumers who are looking for both form and function.

Opportunities for Expansion in Electric Vehicle Markets

The rise of electric vehicles (EVs) presents new opportunities for wheel cover manufacturers. As EVs become more popular, manufacturers are exploring designs and materials that suit the specific needs of electric vehicles. For instance, lightweight wheel covers that reduce drag and improve aerodynamics are particularly important for EVs, where efficiency is paramount. Manufacturers should focus on developing wheel covers tailored to the unique requirements of the EV market.

Challenges Facing the Wheel Cover Industry

Fluctuations in Raw Material Prices and Supply Chain Disruptions

The wheel cover industry faces challenges from fluctuations in raw material prices and ongoing supply chain disruptions. As prices for materials like aluminum and carbon fiber rise, manufacturers may face higher production costs. Additionally, delays in the supply chain can impact the timely availability of wheel covers, affecting sales and production schedules. Companies must focus on securing reliable supply chains and managing material costs effectively.

Counterfeit Products and Quality Control Issues

Counterfeit wheel covers are a growing concern in the industry, as they can undermine the reputation of high-quality products. Maintaining strict quality control measures is essential to ensure that customers receive durable, well-made wheel covers. Manufacturers must invest in anti-counterfeit technologies, such as holograms or digital verification tools, to protect their brands and ensure that customers are buying authentic products.

Meeting Consumer Expectations for Durability and Design

As consumer demand for both durability and design continues to grow, manufacturers must strike a balance between creating aesthetically pleasing wheel covers and ensuring that they are long-lasting and functional. High-performance materials, attention to design, and rigorous testing are essential to meet these expectations. Manufacturers who can consistently deliver on both aspects will gain a competitive edge in the market.

Conclusion

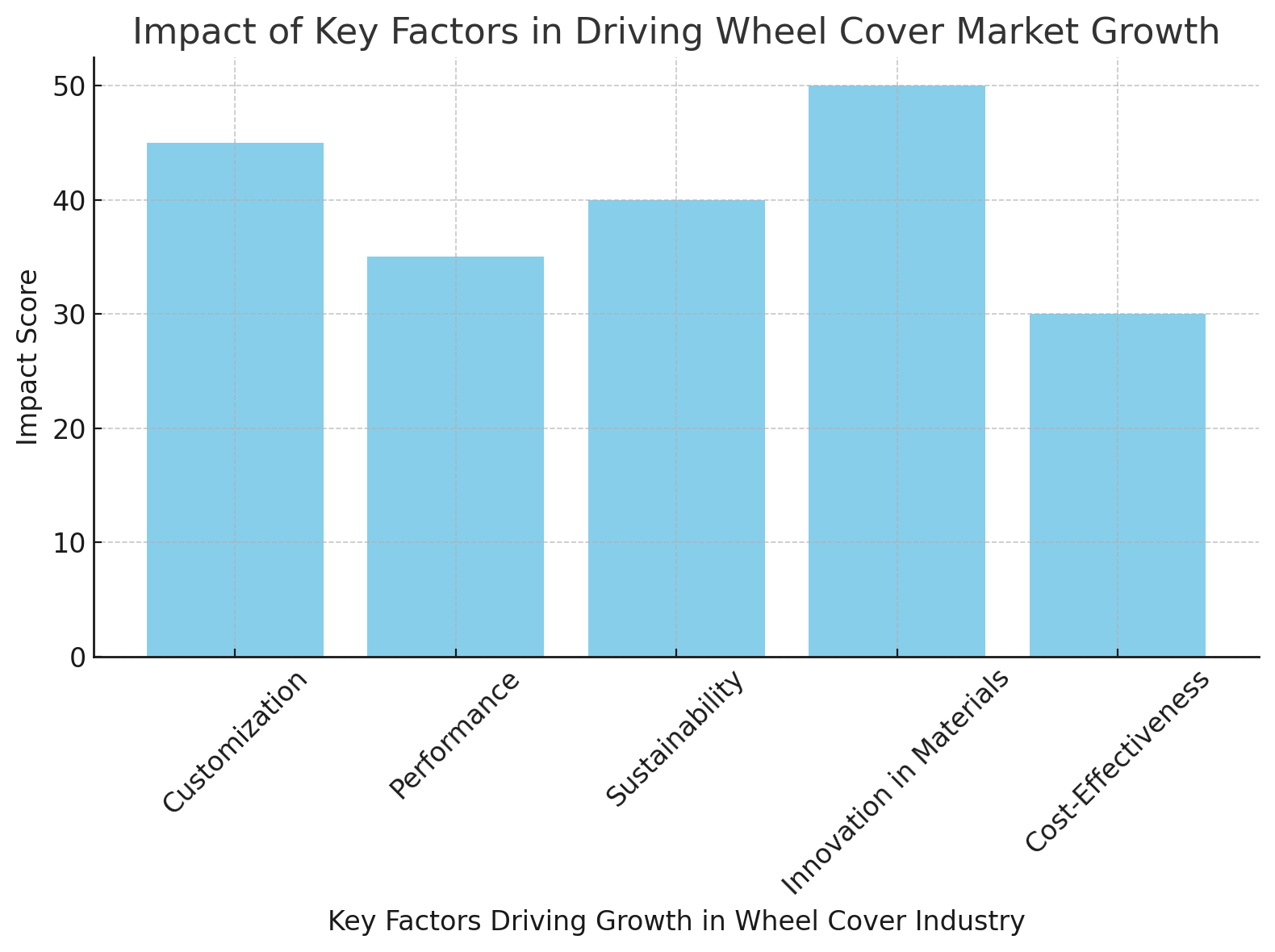

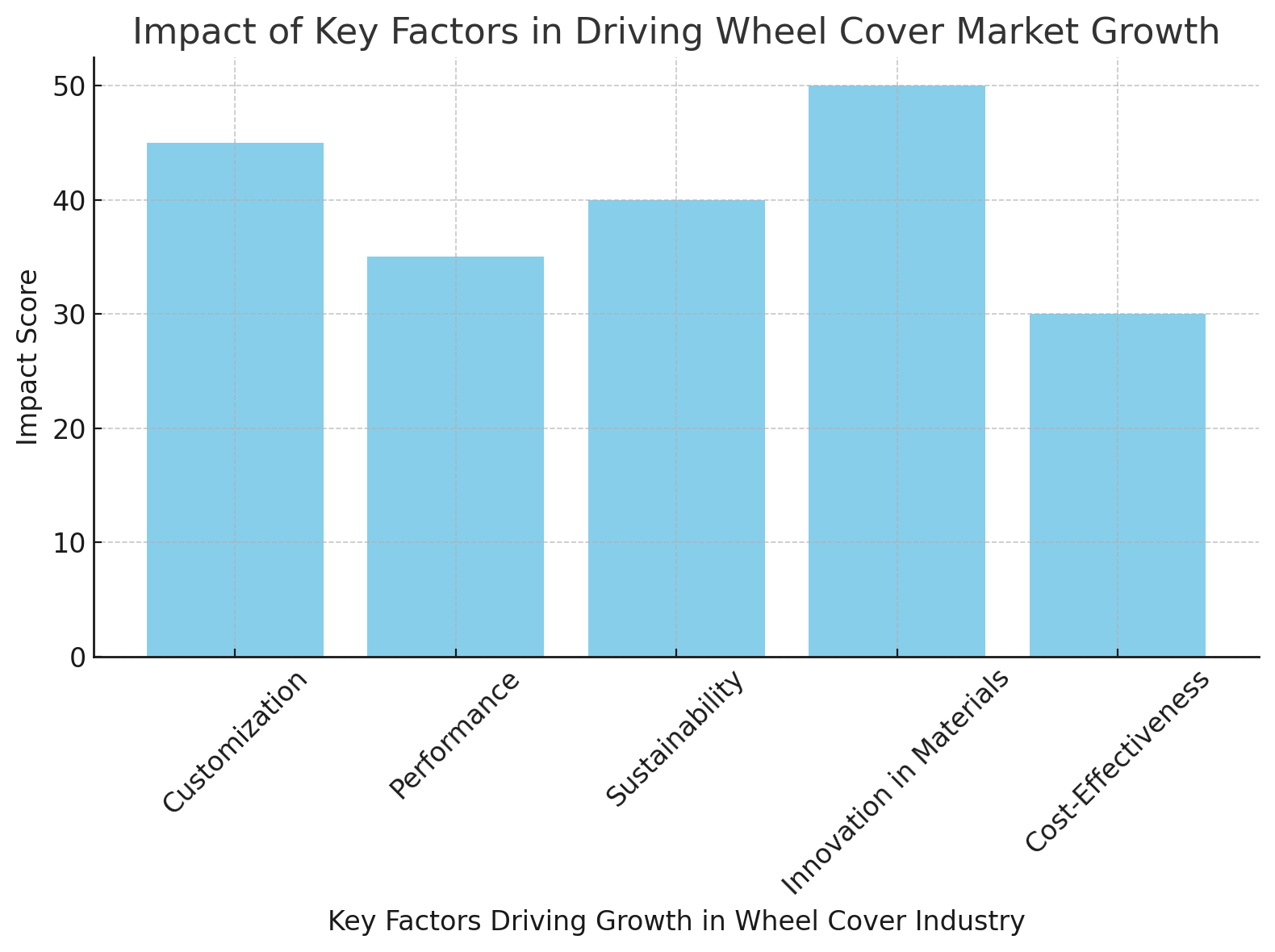

Quality wheel covers are playing a key role in sustainable growth in automotive manufacturing and the aftermarket. With increasing demand for customization, performance, and eco-friendly solutions, innovations in materials and design are shaping the future of the industry. Manufacturers focused on high-quality materials and sustainable practices will thrive in this competitive market. Companies like SEIKOSHOWA are driving this change, offering high-performance, sustainable wheel covers that meet the evolving needs of consumers and manufacturers.

FAQ

Q: What are quality wheel covers and why are they important?

A: Quality wheel covers are essential for vehicle performance, aesthetics, and sustainability. They improve aerodynamics, protect wheels, and provide customization options while supporting eco-friendly manufacturing.

Q: How do wheel covers contribute to vehicle performance?

A: High-quality wheel covers enhance vehicle performance by reducing drag, improving fuel efficiency, and offering durable protection against road conditions.

Q: Are there eco-friendly options for wheel covers?

A: Yes, many manufacturers are focusing on sustainable materials like recycled plastics and biodegradable composites to create eco-friendly wheel covers.

Q: How do aftermarket wheel covers differ from OEM options?

A: Aftermarket wheel covers allow for more customization in design and materials, offering personalized styles and better performance enhancements compared to OEM options.

Q: Why is innovation in wheel cover materials important?

A: Innovation in materials, such as carbon fiber and lightweight alloys, helps improve the durability, performance, and sustainability of wheel covers, meeting growing consumer demands for high-quality products.

Q: What is the impact of wheel covers on the automotive aftermarket?

A: Wheel covers in the aftermarket provide consumers with a cost-effective way to personalize vehicles, enhance performance, and protect wheels, driving growth in this sector.